Unleash the Power of IPE with WL Fuller's Stainless Steel Tools

- David Picozzi

- Jun 13, 2023

- 2 min read

Updated: Jun 13, 2023

There's something profoundly satisfying about creating something beautiful from robust, dense woods such as IPE. Their sheer strength and enduring charm make them the perfect material for projects that need to withstand time and weather. However, taming these hardy boards requires a superior toolkit, one designed specifically for the job. At WL Fuller, we've risen to this challenge with our Stainless Steel "Type K" countersinks and plug cutters.

Say Hello to Efficiency: The "Type K" Countersink

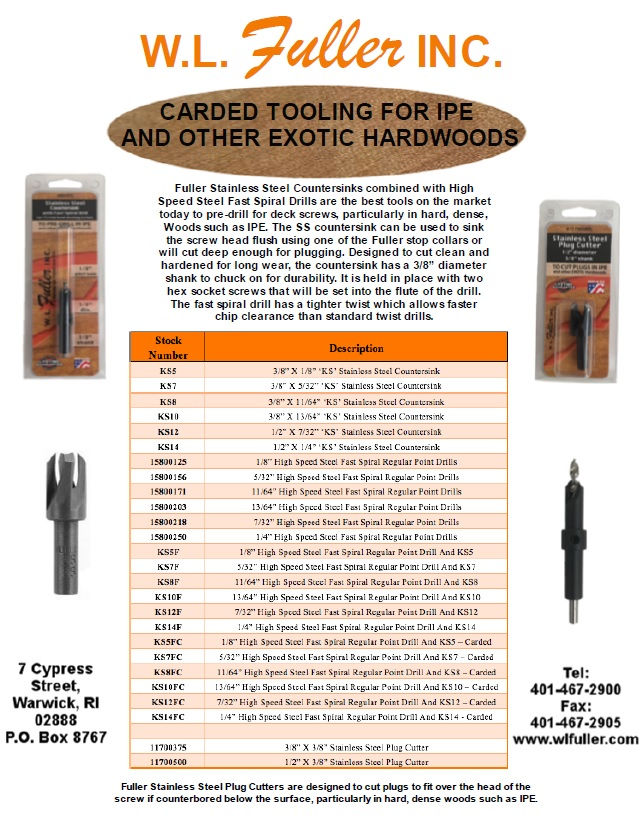

Our Stainless Steel "Type K" countersinks have been meticulously engineered with the toughness of IPE and similar woods in mind. Generic countersinks often pale in comparison when faced with the resilience of IPE, but our countersinks, hardened for long wear, effortlessly produce clean cuts time and time again.

Designed for accuracy and endurance, these countersinks feature a 3/8" diameter shank to ensure a stable grip. The countersink is securely held in place with two hex socket screws set into the flute of the drill. This design ensures a steadfast connection between the countersink and the drill, creating a one-step process for drilling and countersinking.

This efficient combination eliminates the need for pre-drilling. Just insert the countersink with the drill bit locked in, and you're ready to create a perfectly sized hole and countersink in one go. You can choose to sink the screw head flush or cut deep enough for plugging, offering flexibility for the final aesthetic of your project.

The Need for Speed: High-Speed Fast Spiral Drills

When working with hard, dense woods, standard twist drills often struggle with chip clearance, slowing down your work process. This is why we include high-speed fast spiral drills. With a tighter twist, they enable faster chip clearance, drastically speeding up your work without compromising on precision or quality.

Making Plugging Easy: Stainless Steel Plug Cutters

To complement the efficiency of our countersinks, we've developed our stainless steel plug cutters. If you opt to counterbore your screws below the surface, these plug cutters are your go-to tool to produce custom plugs from the same IPE wood. The result is a seamlessly blended, aesthetically pleasing finish that doesn't compromise the integrity of your project.

How To Work With Our Tools

Drill and countersink: Position the "Type K" countersink with the drill bit locked in at the desired location. Proceed to drill, creating the hole and the countersink in one easy step.

Drive the screw: Next, drive in your screw. If you've countersunk to the correct depth, the screw head will sit below the surface of the wood.

Create and install the plug: Finally, if you've decided to go below the surface, use the plug cutter to create a plug from a scrap piece of IPE. This plug can then be glued into the hole above the screw for a smooth, clean finish.

In a nutshell, our suite of stainless steel tools is your comprehensive solution for working with dense woods like IPE. Each tool has been thoughtfully crafted to make your work easier and more efficient. So, go ahead and unlock the potential of your next IPE project with a Fuller toolkit. Believe us; it's an investment worth making!

David Picozzi

W. L. Fuller Inc

Comments